License

Attribution-ShareAlike 4.0 International

=======================================================================

Creative Commons Corporation ("Creative Commons") is not a law firm and

does not provide legal services or legal advice. Distribution of

Creative Commons public licenses does not create a lawyer-client or

other relationship. Creative Commons makes its licenses and related

information available on an "as-is" basis. Creative Commons gives no

warranties regarding its licenses, any material licensed under their

terms and conditions, or any related information. Creative Commons

disclaims all liability for damages resulting from their use to the

fullest extent possible.

Using Creative Commons Public Licenses

Creative Commons public licenses provide a standard set of terms and

conditions that creators and other rights holders may use to share

original works of authorship and other material subject to copyright

and certain other rights specified in the public license below. The

following considerations are for informational purposes only, are not

exhaustive, and do not form part of our licenses.

Considerations for licensors: Our public licenses are

intended for use by those authorized to give the public

permission to use material in ways otherwise restricted by

copyright and certain other rights. Our licenses are

irrevocable. Licensors should read and understand the terms

and conditions of the license they choose before applying it.

Licensors should also secure all rights necessary before

applying our licenses so that the public can reuse the

material as expected. Licensors should clearly mark any

material not subject to the license. This includes other CC-

licensed material, or material used under an exception or

limitation to copyright. More considerations for licensors:

wiki.creativecommons.org/Considerations_for_licensors

Considerations for the public: By using one of our public

licenses, a licensor grants the public permission to use the

licensed material under specified terms and conditions. If

the licensor's permission is not necessary for any reason--for

example, because of any applicable exception or limitation to

copyright--then that use is not regulated by the license. Our

licenses grant only permissions under copyright and certain

other rights that a licensor has authority to grant. Use of

the licensed material may still be restricted for other

reasons, including because others have copyright or other

rights in the material. A licensor may make special requests,

such as asking that all changes be marked or described.

Although not required by our licenses, you are encouraged to

respect those requests where reasonable. More considerations

for the public:

wiki.creativecommons.org/Considerations_for_licensees

=======================================================================

Creative Commons Attribution-ShareAlike 4.0 International Public

License

By exercising the Licensed Rights (defined below), You accept and agree

to be bound by the terms and conditions of this Creative Commons

Attribution-ShareAlike 4.0 International Public License ("Public

License"). To the extent this Public License may be interpreted as a

contract, You are granted the Licensed Rights in consideration of Your

acceptance of these terms and conditions, and the Licensor grants You

such rights in consideration of benefits the Licensor receives from

making the Licensed Material available under these terms and

conditions.

Section 1 -- Definitions.

a. Adapted Material means material subject to Copyright and Similar

Rights that is derived from or based upon the Licensed Material

and in which the Licensed Material is translated, altered,

arranged, transformed, or otherwise modified in a manner requiring

permission under the Copyright and Similar Rights held by the

Licensor. For purposes of this Public License, where the Licensed

Material is a musical work, performance, or sound recording,

Adapted Material is always produced where the Licensed Material is

synched in timed relation with a moving image.

b. Adapter's License means the license You apply to Your Copyright

and Similar Rights in Your contributions to Adapted Material in

accordance with the terms and conditions of this Public License.

c. BY-SA Compatible License means a license listed at

creativecommons.org/compatiblelicenses, approved by Creative

Commons as essentially the equivalent of this Public License.

d. Copyright and Similar Rights means copyright and/or similar rights

closely related to copyright including, without limitation,

performance, broadcast, sound recording, and Sui Generis Database

Rights, without regard to how the rights are labeled or

categorized. For purposes of this Public License, the rights

specified in Section 2(b)(1)-(2) are not Copyright and Similar

Rights.

e. Effective Technological Measures means those measures that, in the

absence of proper authority, may not be circumvented under laws

fulfilling obligations under Article 11 of the WIPO Copyright

Treaty adopted on December 20, 1996, and/or similar international

agreements.

f. Exceptions and Limitations means fair use, fair dealing, and/or

any other exception or limitation to Copyright and Similar Rights

that applies to Your use of the Licensed Material.

g. License Elements means the license attributes listed in the name

of a Creative Commons Public License. The License Elements of this

Public License are Attribution and ShareAlike.

h. Licensed Material means the artistic or literary work, database,

or other material to which the Licensor applied this Public

License.

i. Licensed Rights means the rights granted to You subject to the

terms and conditions of this Public License, which are limited to

all Copyright and Similar Rights that apply to Your use of the

Licensed Material and that the Licensor has authority to license.

j. Licensor means the individual(s) or entity(ies) granting rights

under this Public License.

k. Share means to provide material to the public by any means or

process that requires permission under the Licensed Rights, such

as reproduction, public display, public performance, distribution,

dissemination, communication, or importation, and to make material

available to the public including in ways that members of the

public may access the material from a place and at a time

individually chosen by them.

l. Sui Generis Database Rights means rights other than copyright

resulting from Directive 96/9/EC of the European Parliament and of

the Council of 11 March 1996 on the legal protection of databases,

as amended and/or succeeded, as well as other essentially

equivalent rights anywhere in the world.

m. You means the individual or entity exercising the Licensed Rights

under this Public License. Your has a corresponding meaning.

Section 2 -- Scope.

a. License grant.

1. Subject to the terms and conditions of this Public License,

the Licensor hereby grants You a worldwide, royalty-free,

non-sublicensable, non-exclusive, irrevocable license to

exercise the Licensed Rights in the Licensed Material to:

a. reproduce and Share the Licensed Material, in whole or

in part; and

b. produce, reproduce, and Share Adapted Material.

2. Exceptions and Limitations. For the avoidance of doubt, where

Exceptions and Limitations apply to Your use, this Public

License does not apply, and You do not need to comply with

its terms and conditions.

3. Term. The term of this Public License is specified in Section

6(a).

4. Media and formats; technical modifications allowed. The

Licensor authorizes You to exercise the Licensed Rights in

all media and formats whether now known or hereafter created,

and to make technical modifications necessary to do so. The

Licensor waives and/or agrees not to assert any right or

authority to forbid You from making technical modifications

necessary to exercise the Licensed Rights, including

technical modifications necessary to circumvent Effective

Technological Measures. For purposes of this Public License,

simply making modifications authorized by this Section 2(a)

(4) never produces Adapted Material.

5. Downstream recipients.

a. Offer from the Licensor -- Licensed Material. Every

recipient of the Licensed Material automatically

receives an offer from the Licensor to exercise the

Licensed Rights under the terms and conditions of this

Public License.

b. Additional offer from the Licensor -- Adapted Material.

Every recipient of Adapted Material from You

automatically receives an offer from the Licensor to

exercise the Licensed Rights in the Adapted Material

under the conditions of the Adapter's License You apply.

c. No downstream restrictions. You may not offer or impose

any additional or different terms or conditions on, or

apply any Effective Technological Measures to, the

Licensed Material if doing so restricts exercise of the

Licensed Rights by any recipient of the Licensed

Material.

6. No endorsement. Nothing in this Public License constitutes or

may be construed as permission to assert or imply that You

are, or that Your use of the Licensed Material is, connected

with, or sponsored, endorsed, or granted official status by,

the Licensor or others designated to receive attribution as

provided in Section 3(a)(1)(A)(i).

b. Other rights.

1. Moral rights, such as the right of integrity, are not

licensed under this Public License, nor are publicity,

privacy, and/or other similar personality rights; however, to

the extent possible, the Licensor waives and/or agrees not to

assert any such rights held by the Licensor to the limited

extent necessary to allow You to exercise the Licensed

Rights, but not otherwise.

2. Patent and trademark rights are not licensed under this

Public License.

3. To the extent possible, the Licensor waives any right to

collect royalties from You for the exercise of the Licensed

Rights, whether directly or through a collecting society

under any voluntary or waivable statutory or compulsory

licensing scheme. In all other cases the Licensor expressly

reserves any right to collect such royalties.

Section 3 -- License Conditions.

Your exercise of the Licensed Rights is expressly made subject to the

following conditions.

a. Attribution.

1. If You Share the Licensed Material (including in modified

form), You must:

a. retain the following if it is supplied by the Licensor

with the Licensed Material:

i. identification of the creator(s) of the Licensed

Material and any others designated to receive

attribution, in any reasonable manner requested by

the Licensor (including by pseudonym if

designated);

ii. a copyright notice;

iii. a notice that refers to this Public License;

iv. a notice that refers to the disclaimer of

warranties;

v. a URI or hyperlink to the Licensed Material to the

extent reasonably practicable;

b. indicate if You modified the Licensed Material and

retain an indication of any previous modifications; and

c. indicate the Licensed Material is licensed under this

Public License, and include the text of, or the URI or

hyperlink to, this Public License.

2. You may satisfy the conditions in Section 3(a)(1) in any

reasonable manner based on the medium, means, and context in

which You Share the Licensed Material. For example, it may be

reasonable to satisfy the conditions by providing a URI or

hyperlink to a resource that includes the required

information.

3. If requested by the Licensor, You must remove any of the

information required by Section 3(a)(1)(A) to the extent

reasonably practicable.

b. ShareAlike.

In addition to the conditions in Section 3(a), if You Share

Adapted Material You produce, the following conditions also apply.

1. The Adapter's License You apply must be a Creative Commons

license with the same License Elements, this version or

later, or a BY-SA Compatible License.

2. You must include the text of, or the URI or hyperlink to, the

Adapter's License You apply. You may satisfy this condition

in any reasonable manner based on the medium, means, and

context in which You Share Adapted Material.

3. You may not offer or impose any additional or different terms

or conditions on, or apply any Effective Technological

Measures to, Adapted Material that restrict exercise of the

rights granted under the Adapter's License You apply.

Section 4 -- Sui Generis Database Rights.

Where the Licensed Rights include Sui Generis Database Rights that

apply to Your use of the Licensed Material:

a. for the avoidance of doubt, Section 2(a)(1) grants You the right

to extract, reuse, reproduce, and Share all or a substantial

portion of the contents of the database;

b. if You include all or a substantial portion of the database

contents in a database in which You have Sui Generis Database

Rights, then the database in which You have Sui Generis Database

Rights (but not its individual contents) is Adapted Material,

including for purposes of Section 3(b); and

c. You must comply with the conditions in Section 3(a) if You Share

all or a substantial portion of the contents of the database.

For the avoidance of doubt, this Section 4 supplements and does not

replace Your obligations under this Public License where the Licensed

Rights include other Copyright and Similar Rights.

Section 5 -- Disclaimer of Warranties and Limitation of Liability.

a. UNLESS OTHERWISE SEPARATELY UNDERTAKEN BY THE LICENSOR, TO THE

EXTENT POSSIBLE, THE LICENSOR OFFERS THE LICENSED MATERIAL AS-IS

AND AS-AVAILABLE, AND MAKES NO REPRESENTATIONS OR WARRANTIES OF

ANY KIND CONCERNING THE LICENSED MATERIAL, WHETHER EXPRESS,

IMPLIED, STATUTORY, OR OTHER. THIS INCLUDES, WITHOUT LIMITATION,

WARRANTIES OF TITLE, MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, NON-INFRINGEMENT, ABSENCE OF LATENT OR OTHER DEFECTS,

ACCURACY, OR THE PRESENCE OR ABSENCE OF ERRORS, WHETHER OR NOT

KNOWN OR DISCOVERABLE. WHERE DISCLAIMERS OF WARRANTIES ARE NOT

ALLOWED IN FULL OR IN PART, THIS DISCLAIMER MAY NOT APPLY TO YOU.

b. TO THE EXTENT POSSIBLE, IN NO EVENT WILL THE LICENSOR BE LIABLE

TO YOU ON ANY LEGAL THEORY (INCLUDING, WITHOUT LIMITATION,

NEGLIGENCE) OR OTHERWISE FOR ANY DIRECT, SPECIAL, INDIRECT,

INCIDENTAL, CONSEQUENTIAL, PUNITIVE, EXEMPLARY, OR OTHER LOSSES,

COSTS, EXPENSES, OR DAMAGES ARISING OUT OF THIS PUBLIC LICENSE OR

USE OF THE LICENSED MATERIAL, EVEN IF THE LICENSOR HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH LOSSES, COSTS, EXPENSES, OR

DAMAGES. WHERE A LIMITATION OF LIABILITY IS NOT ALLOWED IN FULL OR

IN PART, THIS LIMITATION MAY NOT APPLY TO YOU.

c. The disclaimer of warranties and limitation of liability provided

above shall be interpreted in a manner that, to the extent

possible, most closely approximates an absolute disclaimer and

waiver of all liability.

Section 6 -- Term and Termination.

a. This Public License applies for the term of the Copyright and

Similar Rights licensed here. However, if You fail to comply with

this Public License, then Your rights under this Public License

terminate automatically.

b. Where Your right to use the Licensed Material has terminated under

Section 6(a), it reinstates:

1. automatically as of the date the violation is cured, provided

it is cured within 30 days of Your discovery of the

violation; or

2. upon express reinstatement by the Licensor.

For the avoidance of doubt, this Section 6(b) does not affect any

right the Licensor may have to seek remedies for Your violations

of this Public License.

c. For the avoidance of doubt, the Licensor may also offer the

Licensed Material under separate terms or conditions or stop

distributing the Licensed Material at any time; however, doing so

will not terminate this Public License.

d. Sections 1, 5, 6, 7, and 8 survive termination of this Public

License.

Section 7 -- Other Terms and Conditions.

a. The Licensor shall not be bound by any additional or different

terms or conditions communicated by You unless expressly agreed.

b. Any arrangements, understandings, or agreements regarding the

Licensed Material not stated herein are separate from and

independent of the terms and conditions of this Public License.

Section 8 -- Interpretation.

a. For the avoidance of doubt, this Public License does not, and

shall not be interpreted to, reduce, limit, restrict, or impose

conditions on any use of the Licensed Material that could lawfully

be made without permission under this Public License.

b. To the extent possible, if any provision of this Public License is

deemed unenforceable, it shall be automatically reformed to the

minimum extent necessary to make it enforceable. If the provision

cannot be reformed, it shall be severed from this Public License

without affecting the enforceability of the remaining terms and

conditions.

c. No term or condition of this Public License will be waived and no

failure to comply consented to unless expressly agreed to by the

Licensor.

d. Nothing in this Public License constitutes or may be interpreted

as a limitation upon, or waiver of, any privileges and immunities

that apply to the Licensor or You, including from the legal

processes of any jurisdiction or authority.

=======================================================================

Creative Commons is not a party to its public licenses.

Notwithstanding, Creative Commons may elect to apply one of its public

licenses to material it publishes and in those instances will be

considered the “Licensor.” The text of the Creative Commons public

licenses is dedicated to the public domain under the CC0 Public Domain

Dedication. Except for the limited purpose of indicating that material

is shared under a Creative Commons public license or as otherwise

permitted by the Creative Commons policies published at

creativecommons.org/policies, Creative Commons does not authorize the

use of the trademark "Creative Commons" or any other trademark or logo

of Creative Commons without its prior written consent including,

without limitation, in connection with any unauthorized modifications

to any of its public licenses or any other arrangements,

understandings, or agreements concerning use of licensed material. For

the avoidance of doubt, this paragraph does not form part of the public

licenses.

Creative Commons may be contacted at creativecommons.org.

Cost Modelling

Key issues in selection:

- Component function, including materials and shape, form, and assembly

- Manufacturing process may greatly affect material properties, such as yield strength

- Similarly, the material will likely decide the manufacturing process

- Cost of a material and manufacture

The main requirement for a product to be viable is

Cost modelling equation:

Shaping Processes

Casting

- Can be used for large size range

- Molten metal poured into solid mould to give shape

- Heat removed leads to shrinkage

- We need to be able to melt the metal and handlethe molten metal

- Mould degradation by the liquid metal needs to be considered

- Heat flowing from the molten metal into the mould causes a drop in temperature so solidification starts from outside inwards

- Rate of solidification depends on rate of heat flow into mould

Types of Mould

Expendable mould (sand, plaster, ceramic)

- The mould is used once, being broken to release the casting

- Can have multiple use or single use pattern (investment and lost foam casting

Multiple mold casting

- Die casting (pressure die casting)

- Permanent mould casting (gravity die casting)

Sand Casting

- Wide range of metals can be cast

- Almost no limit to size and shape of casting

- Poorer tolerances than other proces, rough surface texture

- Slow

- Economic for a low number of castings

- Applications include cylinder blocks and large pipe fittings

Investment Casting

- A high cost process

- Used mostly for complex shapes, such as sculptures, jewellery, and gas turbine blades

- Can be used for a wide range of metals

- Very high precision and surface finish

Make a master die

Make wax pattern by casting wax into master die

Coat wax pattern with investment material

- First with a slurry of water and fine ceramic to capture fine details

- Then coat with stucco, which is a thicker coating for strength

Heat mould to melt wax out, bake and preheat mould

Pour in molten metal

Wait for solidification, break mould when done

Permanent Mould Casting (Gravity Die Casting)

- Mould cavity is machined into mating metal blocks

- Molten material poured into mould

- Mould material is cast iron, steel, bronze, graphite

- Mould must disassebmble without locking

- Mould is expensive but can be reused (typically around 25k times)

- Mould life is reduce by casting high meling point metals

- Good surface finish and dimensional accuracy

- Cooling is rapid therefore high production rates

- Example use is a piston

Die Casting (High Pressure Die Casting)

- Dies must be able to withstand high pressure

- 0.1 mm slits at parting lines provide escape for air

- Dies are made of expensive tool steels

- High volume production is necessary to justify costs

- Generally limited to low viscosity, low melting point, non ferrous metals like Al, Zn, Mg, and Pb

- Good surface finish

- Precision castings with thickness between 0.75 mm and 12 mm

Design of Castings

Distribute castings evently around parting planes

Need to be able to get patterns out of moulds and casting out of moulds where applicable

No re-entrants (complex multi-part moulds may be able to avoid this restriction)

Draft angle between surfaces

- Need to be able to get solid patternout of mould in sand casting

- Need to be able to get solid casting out of mould in die casting

Allow for shrinkage — dimensions of casting mould/pattern needs to be made so that part is desired size after shrinkage

Avoid rapid change in section or direction:

Solifidification of Metals

- How well the liquid fills detail depends on viscosity of liquid

- During freezing, latent heat of fusion is removed

- During freezing, material is a solid/liquid mixture

- There is a significant (~7 %v) shrinkage during solidification

- Heat flows down steepest thermal gradient so usually there is an actively cooled section

- Thin sections freeze faster than thick sections

Castability

- Low melting point

- Low viscosity and surface tension

- Low solidification contraction

- Low thermal capacity and high conductibity

- Low solubility

- Not contaminated by air

Deformation

When a metal is plastically deformed, dislocations move and multiply.

Annealed aluminium may have a dislocatio density of around 200 m per mm. This is a very low amount. A heavily cold worked piece may have a density of up to 270 km per mm.

As dislocation density increases, the dislocations impede the motion of other dislocations. This means that to continue plastically deforming, more stress has to be applied.

The stress goes down towards the end of the graph due to the material necking, meaning the material gets thinner. This means that the engineering stress is lower as the true area is lower. The true stress, however, is going up:

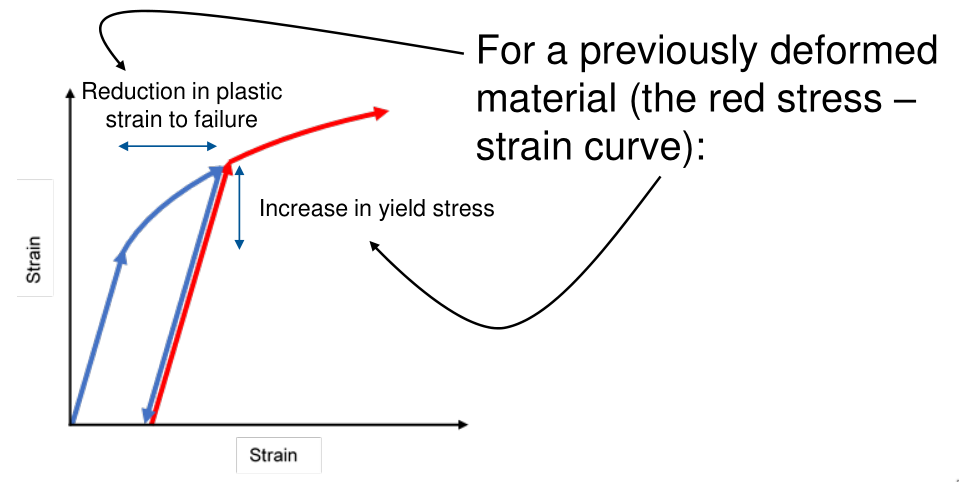

Effect of Prior Deformation (Work Hardening)

See here for more information

Effect of Temperature (Diffusion)

In an alloy, atoms tend to migrate from regions of high concentration to low concentration. This is diffusion.

More information on diffusion here.

Annealing

Annealing is a process by which a component is heated to reduce work hardening.

These are diffusional processes and only occur at higher temperatures.

When the temperature of a material, , it is said to be hot. A material being worked on hot has its deformations eliminated as fast as they are created.

A material is said to be cold when .

Powder Processes

Poweders can plowflow if forces between them are low

With small amounts of binder, they can form “plastic” materials like clay.

A slurry can be formed with a liquid carrier (where there is enough liquid to separate particles). In a slurry, often you want to reduce liquid content but avoid the particles touching or attracting each other. Adding a deflocculant1 results in the formation of a stable slip.

Making the powders is often quite expensive when you have a controlled size distribution.

Clay and Ceramics

Clay is an abundant raw material but it needs to be milled and screen for a controlled size distribution. When mixed with water it forms a plastic material.

Structural clay products include bricks, tiles, and pipes. Other proucts include whitewares such as porcelain, pottery, and tableware.

Ways to form the clay include pressing, isostatic pressing, extrusion, and machining.

Engineering ceramics (e.g. silicon carbide, alumina) are shaped with small amounts of binder — commonly pressed or isostatically pressed.

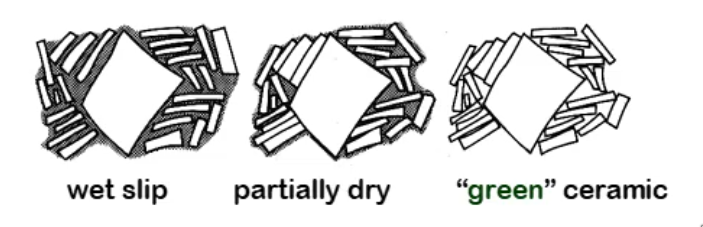

Slip Casting

- Pour slip into a mould (e.g. plaster of Paris)

- The mould is extremely water absorbing. This results in the remaining part developing some structural integrity.

- Remove the mould and place in the oven to reduce water content.

- Fire to harden

- Add glaze and fire again.

Drying leads to shrinkage and potential cracking. It also gives strength and allows for handling and maybe machining.

Sintering of Metals and Ceramics

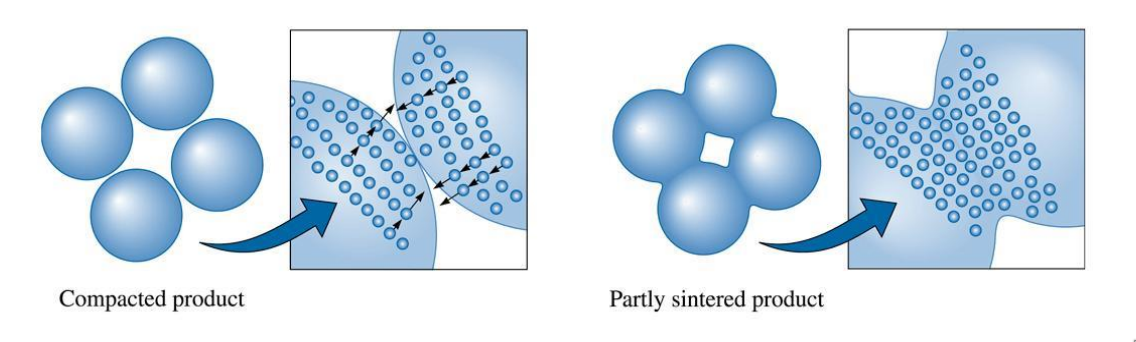

Atoms diffuse to points of contact, creating bridges and reducing the pore size. Diffusion is driven by a desire to reduce the surface area as surfaces are regions of high energy.

Powdering Metallurgy

- Competitive with processes like casting, forging, machining

- Used when the melting point is too high, a chemical reaction occurs at melting point, the part is too hard to machine, or a very large quantity (on the order of 100 000) of the part is needed

- Nearly 70% of parts produced is by powder metallurgy

- Good dimensional accuracy

- Controlloable porosity

- Size range from balls in ball point pens to parts weighing 50 kg

Basic steps of powder metallurgy:

Powder production (commonly atomization) — this is often a costly process and you must minimize oxidation of the metal

Blending/mixing — add binders to keep the particles together and lubricants to reduce damage to dies and aid consolidation

Powder consolidation

- Shaping in a die

- 100-900 MPa of pressure applied

- Fast process as no heat needs to be removed

Sintering at to

Shaping equipment has no requirement to be able to withstand high temperatures and the sintering equipment does not have the need for complex designs. This separates problems, making them easier to design.

The pressing equipment is costly but the time spent pressing is quite small, allowing for greater throughput. Additionally, the furnace can operate continuously and is simple and cost effective.

Green Density

The green density is a fraction of the true density. A low green density will result in high shrinkage on sintering.

Moulding

Moulding is a shaping process used for viscous materials (typically polymers and glasses). Here the material can hold a shape unsupported but not for very long or under even small stresses.

In order to mould a material we must raise the temperature above the glass transition temperature, . At this temperature, the C-C bond in the chapolymer chain are able to easily rotate around each other.

Large side chains or molecules on the main chain make it harder to rotate these bonds, making higher. Polar groups (e.g. chloride, cynaide, and hydroxide) have also hinder bond rotation.

More information about polymers here.

Extrusion

Extrusion produced parts of constant cross section, like pipes and rods. The process is used primarily with thermoplastics and 60% of polymers are prepared by extrusion.

Blow Moulding

Blow moulding is a rapid process with low labour costs. It produces hollow components that do not require a constant thickness, such as bottles, petrol tanks, and drums. Common materials to blow mould are HDPE, LDPE, PP, PET, and PVC.

There are three common types of blow moulding:

- Extrusion blow moulding

- Injetion blow moulding

- Stretch-blow processes

However, they involve the following stages:

- A tubular preform, called a parison (a word I haven’t been able to remember since GCSE) is produced by either extrusion of injection moulding

- The parison is transferred into a cooled split-mould

- The parison is sealed and inflated to take up the shape of the mould

- The moulding is let to cool and solifidies under pressure

- The mould is opened and moulding is ejected

Injection Moulding

- Powder or pellets of polymer heated to liquid state (low viscosity)

- Under pressure, the liquid polymer is forced into a mould through a sprue, a small opening

- The pressurized material is held in the mould until it solidifies

- The mould is opened and the part is removed by ejector pins Selection was cancelled by keystroke or right-click.

Theromoplastics are most common in injection moulding. A very high level of detail is attainable through this process and it produced little waste.

Similar to Die Casting, you must consider corners (avoid sharp ones), draft angles (so you can get the part out), and section thickness (using ribs instead is preferable).

Due to the high capital cost, injection moulding is only economical at high production volumes.

Co-Injection Moulding

There is sequential moulding (one after the other) and co-injection moulding (together).

These processes reduce assembly costs by integrating the parts and can use low grade recycled material for the inside of a component. It also allows for a part have to have multiple colours.

This process requires special attention to be payed to shrinking/cooling.

Rotational Moulding

Rotational moulding involves coating the insides of a heated mould with a thermoplastic. It is a low pressure alternative to blow moulding for making hollow components and is used for large components such as storage tanks, boat hulls, kayaks, and cones.

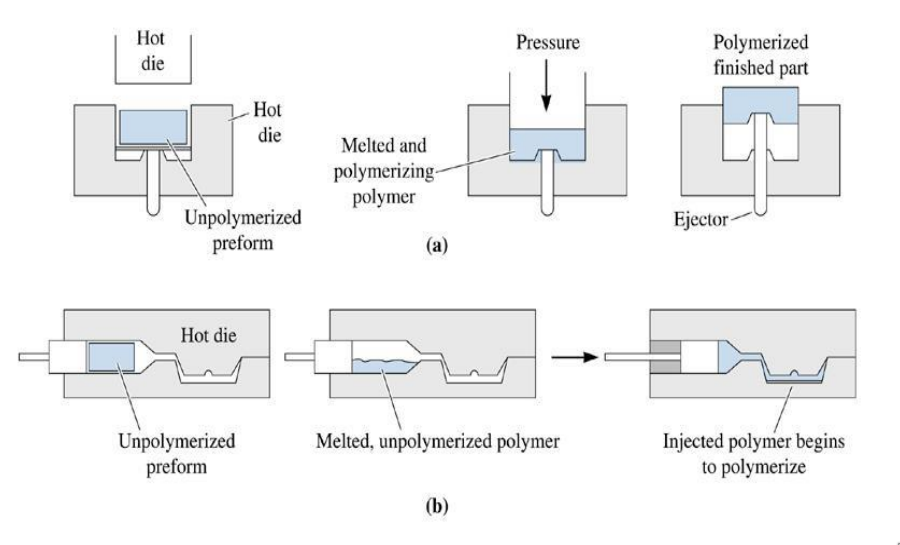

Moulding for Thermosetting Polymers

There are two types:

- Compression moulding

- Transfer moulding

Compression Moulding

For thermoplastics, the mould is cooled before removoal so the part will not lose its shape. Thermosets, however, may be ejected while they are hot so long as curing is complete.

The process is slow but the material only moves a short distance and has lower mould pressures. It also does minimal damage to reinforcing fibres in composites and it is possible to make large parts.

More manual labour is required and has longer cycle times than injection moulding.

Machining Processes

Advantages of Machining Processes

- High precision of geometrical dimensions, tolerances, and surface finishes

- Is able to make one off prototypes in production grade material

- Creates high volume production tooling

- Increasing hard/brittle/fragile/tough materials can only be machines

- Some designs are so complex that machining is the only realistic process to make them with

Disadvantages of Machining Processes

- Material is wasted (as it is a subtractive process)

- Complex parts require expensive machines to make and making them can take a long time

- Parts need to be set up using fixtures. These fixtures get increasingly complex with the part.

- Faster production rates and harder materials wear down the tools.

Glossary

a substance which, when added to scattered particles in suspension, causes a reduction in apparent viscosity. Deflocculants are substances which prevent flocculation by increasing zeta potential and therefore the repulsive forces between particles. (https://digitalfire.com/article/deflocculants%3A+a+detailed+overview)↩︎

page rendered by gronk